April 20, 2021

Five Stars for the Three Rs

Despite the massive changes and shifts in focus brought to so many industries by the Coronavirus pandemic, the three Rs of sustainable packaging continue to remain high on the agenda of global manufacturing and distribution companies.

Much emphasis is also being placed on the most familiar and widespread form of sustainable packaging: ‘recyclables.’ However it’s important to remember that recyclability is just one of the factors behind sustainable packaging solutions and that sustainability has always been built on three pillars or three Rs – “Reduce, Reuse and Recycle.”

“When it comes to designing and producing sustainable packaging as part of a full-service packaging supply system, it’s essential not to forget the other two Rs: reduce and reuse,” says IPL Head of Design, LB Odendaal.

The three Rs of sustainability

“By ‘reducing’ we’re seeking to avoid waste, to streamline our client’s packaging by making it leaner and requiring less material; and thereby saving money, energy and resources,” he states. “By creating packaging for ‘reuse’ we’re enabling the packaging to live on beyond the point of purchase, giving it a purpose beyond the original primary use.”

“For the drink and spirits sector, in particular, many of our packaging solutions have been designed to incorporate a secondary function and promote longevity and reuse. As with other industries such as the numismatic and fragrance sectors, for example, these packs are also often constructed for display purposes,” explains Odendaal.

“Whilst secondary use is not always the core focus when designing luxury packaging, the notion of incorporating a secondary function into package design can also deliver a significant added value component,” he states.

IPL creates reusable packaging

Scotch whisky brand and IPL Packaging customer, Glengoyne, recently won the 2020 Green Packaging Award for the spirits category at The Drinks Business Green Awards. The judges remarked that Glengoyne is “taking a novel environmental approach to luxury packaging” and focused on the second-use ability feature (boxes featured personalisable plaques, peelable labels and removable inner fitments) of the prestige 25YO and 30YO packaging as something never seen before.

“IPL has also supplied and, in several instances, also designed, a variety of packs that convert to extended use: for Buchanan’s whisky – a tin packaging solution was designed to be further utilised as an ice-bucket, for Titleist the packaging can be further used as a sunglasses case, and for Jessica McCormack and French fragrance brand, Ex Nihlio the custom-designed cases can be utilised as bespoke jewellery boxes.”

“Whatever the sector we are packaging for – our approach to process and design is built around efficiency,” continues Odendaal. “It boils down to the following: simplify wherever possible; utilise the most effective materials; minimise the impact on the environment; always strive to be true to the brand values; and never forget the benefit to the end-user.”

The more Rs, the better

“Packaging should incorporate at least one of the three Rs – but the more it incorporates – the better! “To ‘reduce’ we look to simplify components, streamline production processes and transportation, amongst others,” he says. “In much of our packaging, we strive to remove protective polybags where testing proves that the product is not adversely affected. We’ve replaced these with paper or tissue bags in several instances,” he says.

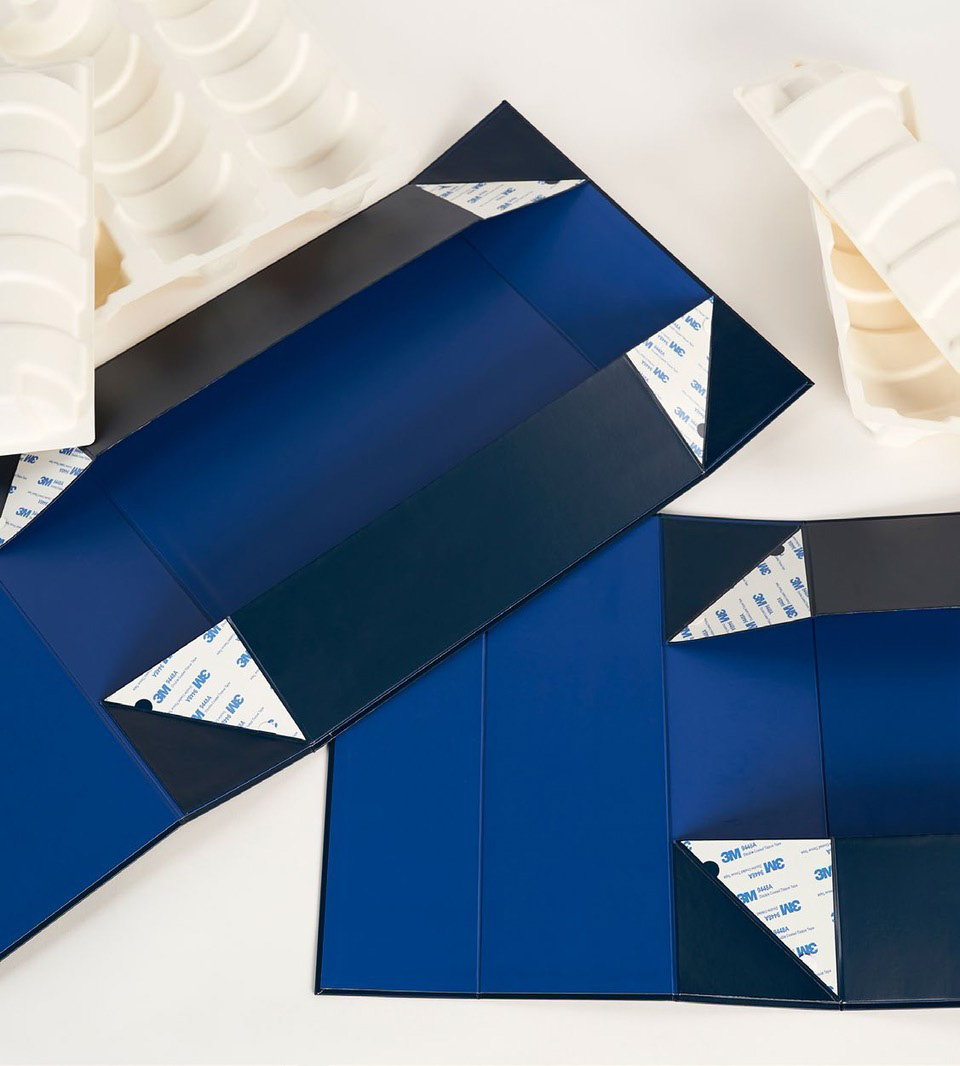

“Similarly, when it comes to transport we always attempt to optimise container utilisation by favouring flat-packaging or part assembly wherever we can. We can also ship directly to any market in the world, produce closest to the destination and select the transport option with the smallest carbon footprint for each delivery.”

“For us though, product, material and process innovation is one of the highest priorities in our business – driving our design and production processes and ‘ticking off the Rs’ in order to allow clients to choose packaging they know falls within their own sustainability goals and promises to consumers.”

___

IPL Packaging is a global luxury packaging supplier with offices in the USA, Europe, Mexico, Asia and Africa. Approved manufacturing is available in several Asian countries, as well as sites in Eastern Europe. We create bespoke, tailored and exclusive packaging for any premium or luxury brand and manage the entire process, from conceptualisation and design to production and delivery.

For more information on packaging solutions or to get an insight into our latest packaging trends, follow us on LinkedIn, Facebook, YouTube or Pinterest. Keep an eye on our news section for insightful articles and innovative ideas around packaging materials, product development and design.

More articles

April 14, 2022

Fly Me to the Moon

December 8, 2020

Kindred Spirits – Glengoyne Single Malt

July 26, 2021

Challenge accepted! …Luxury brands CAN balance consumer preferences AND brand needs through packaging.

June 19, 2024

Dawn of Distinction – ‘The Beginning’ by Echlinville

May 30, 2023

Consistency & Innovation – Finding the Balance in Packaging

April 23, 2021

A New USA Address

November 8, 2021

An IPL perspective – Supply Chain Resilience in a post-pandemic world

August 1, 2023