March 30, 2021

Pulp as a substrate for premium packaging

Consumers are demanding more environmentally-friendly packaging and the luxury market is no exception. Current research shows that over 65% of consumers would opt for green packaging and products over non-sustainable options1. More and more luxury goods are starting to use eco-friendly packaging materials, such as pulp, meaning that packs are designed to be recyclable, protective and have a lower carbon footprint.

Whilst eco-friendly packaging is an objective for most brands it is important for them to note that sustainability no longer equates to boring. In addition, alternatives in the market today ensure that luxury brands do not need to compromise on quality either. Pulp is one such sustainable substrate that holds numerous benefits and performs well as a packaging material.

©Golden Arrow

Pulp has many benefits

There is a major misconception that recycled paper and pulp are low-quality and fibrous. Nowadays, pulp is a strong, durable and highly-customisable solution for luxury packaging. It has excellent cushioning properties, remains unaffected by extreme temperatures and can be moisture-resistant.

What’s more, pulp is economical. It is relatively inexpensive to produce over large production runs, which means that companies can potentially save on new packaging development costs. Its shape and size can be completely tailored to fit the valuable product within with the added benefit of improving product integrity.

Pulp is made from 100% recyclable raw materials. This makes it biodegradable and recyclable. There is little wastewater and harmful byproducts from the process of manufacturing pulp packaging, all benefits which enhance a brand’s reputation in the “sustainable era”.

©Bioplastics News and Mugibson

Types of pulp packaging

Pulp packaging is made from a number of fibrous materials, including recycled paper, cardboard and natural plant fibres. These raw materials determine the colour, texture and strength of the pack. Moulded pulp is formed to shape, so it fits perfectly into a box or holds a premium product tightly. There are four basic types of pulp packaging2:

- Thick-walled – The customised pack is manufactured in a single mould. The thickness ranges between 5 mm and 10 mm.

- Transfer moulded – Produced with one forming and one transfer mould. The thickness ranges between 3 mm and 5 mm.

- Thermoformed – Manufactured using multiple heated moulds. The wall thickness ranges from 2 mm to 4 mm.

- Processed – Produced with a secondary treatment process that gives additional qualities to the pack.

These packs are all designed with complex three-dimensional shapes, making the possibilities almost endless. Thanks to advancements in pulp technology, these sustainable packs can also be created with smooth surfaces for a more sophisticated look and feel; ideal for luxury goods and premium brands.

©James Cropper and The Dieline

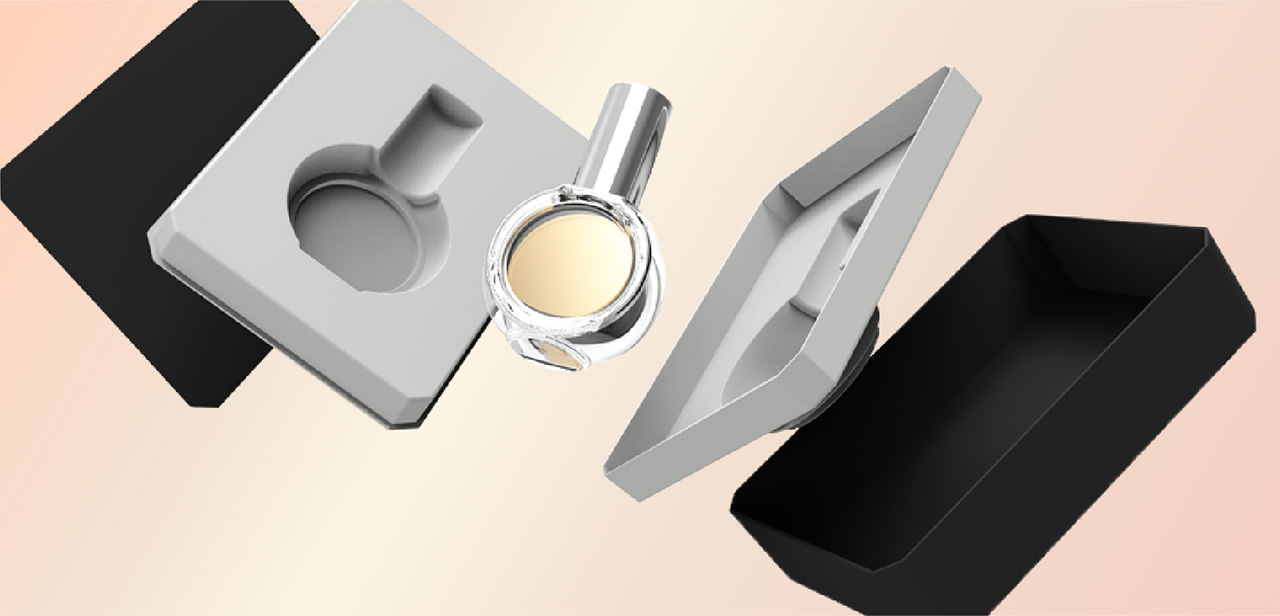

Inner fitments

For some brands, incremental changes towards sustainability are more viable than a complete packaging “makeover”. In these instances, moulded pulp inserts are gaining popularity as a viable alternative to plastic inner components. Outer packaging aesthetics can be kept the same or different sustainable options other than pulp maybe sort. But the characteristics of pulp allow for very flexible fitment options

The growing need for sustainable packaging options has helped to make pulp a suitable choice for luxury brands. Not only is it made from recyclable materials, but it can also be highly customised and easily processed at recycling facilities once it is discarded. Pulp packaging should be a consideration for premium brands looking to improve their sustainability.

Header image: ©Behance

___

IPL Packaging is a global luxury packaging supplier with offices in the USA, Europe, Mexico, Asia and Africa. Approved manufacturing is available in several Asian countries, as well as sites in Eastern Europe. We create bespoke, tailored and exclusive packaging for any premium or luxury brand and manage the entire process, from conceptualisation and design to production and delivery.

For more information on packaging solutions or to get an insight into our latest packaging trends, follow us on LinkedIn, Facebook, YouTube or Pinterest. Keep an eye on our News section for insightful articles and innovative ideas around packaging materials, product development and design.

More articles

July 20, 2022

Sustainable, Sophisticated…and Cost-Savvy Packaging

May 2, 2024

Soaring Celebrations

February 21, 2023

Work Feature – Brugal 1888

October 22, 2020

Beginner’s guide to materials and processes

January 26, 2022

7 Trends Shaping a New Future for the Packaging Industry in 2022

October 5, 2020

Highland (Double) Gold for Tullibardine

April 18, 2024

Luxury Regulated

October 28, 2020