October 28, 2020

Things to watch out for when embossing or debossing

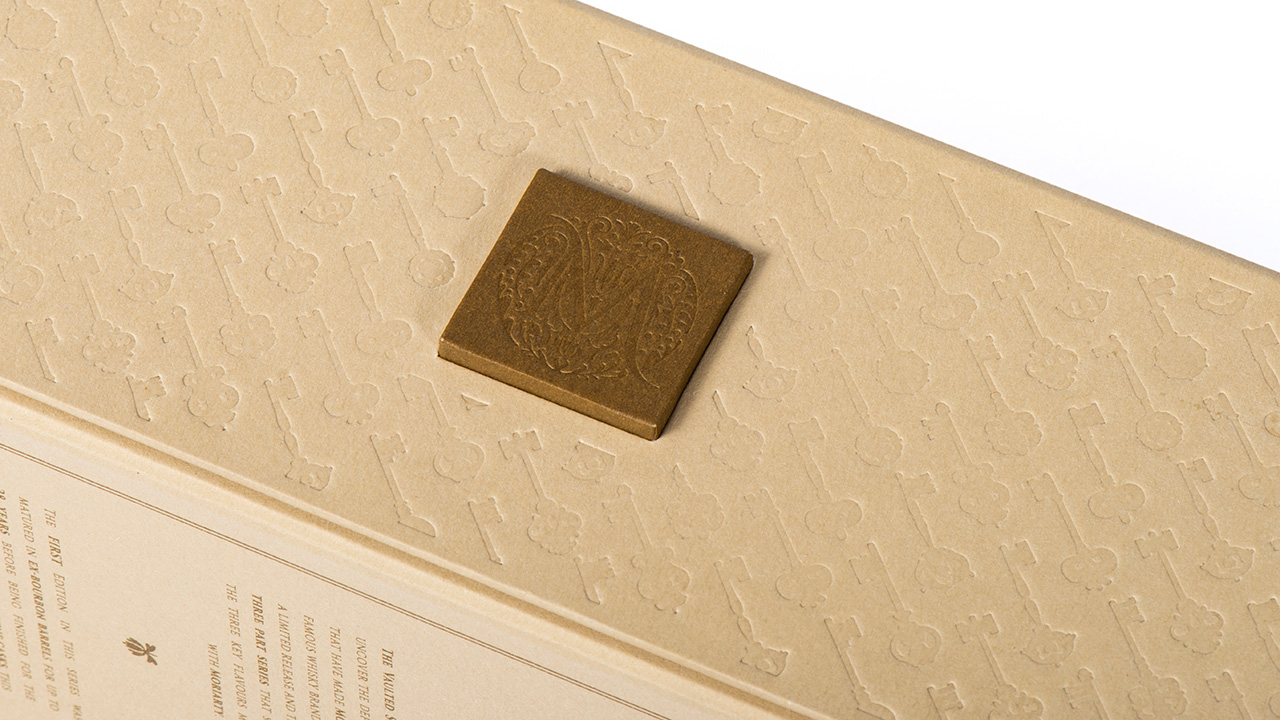

Luxury packaging often has a tactile element that improves the feel of the packaging when in-hand. There are numerous ways to give packaging texture, but two of the most common methods are embossing and debossing. These two processes give dimension to the surface of the packaging and can offer enhanced customisability for premium brands.

When combined with foils, varnishes and other stylistic elements, an emboss or deboss can give the pack an even better quality feel. However, extra care in both the design and production processes are needed when producing packs with raised or lowered surfaces.

The substrate will have limits when embossing

Embossing is often used on paper-based substrates. Some papers work better than others. The design of the embossing tools will determine how far one can challenge the paper’s draw depth before problems start to arise. In addition, printing, foiling and lamination processes are usually done before the emboss. This means that a mistake in the emboss process could ruin all the previous applied finishes.

Whilst paper can be sensitive to the depth of an emboss, so too are substrates such as tin and aluminium sheets. Where an emboss and deboss are intended to be done close to one another, the spacing and depth of allowable draw of the substrate needs to be considered. Metals can also tear in these instances. Deep-drawing of softer metals can also create a noticeable and unwanted print colour change. Whichever substrate is being used, understanding its limitations is always very important.

Registration is a common mistake

One common issue that arises with embossing and debossing is the registration, or alignment, of the embossing tool with the printed artwork. Embossing is not a hugely complicated process, so apart from tool design, the most challenging part of the process is perfectly lining up the tools with the substrate artwork. Registration alignment of the paper with the artwork is done by using simple fixed paper guides on the press.

Poor registration will result in wastage if not picked up immediately. One way to solve misalignment of finer details is to block emboss. This involves embossing a basic shape around more detailed branding or logos. Attempting to emboss or deboss very fine details is not recommended.

Gluing paper to a substrate can flatten an emboss

Another common problem that can arise during the production process is gluing the embossed paper to a greyboard backing or other rigid substrate. When the paper goes through the rolling machine which applies the glue, it can flatten the emboss slightly. This can dilute the embossing or debossing effect, which can be further affected by the pressure of the rollers when the glue is applied.

One way to solve this problem is to glue the paper to the greyboard first and then emboss both board and paper together. This would, however, require a stronger press with more ability to apply pressure. Delamination of paper from the board does need to be considered when using this process.

What about embossing or debossing metals?

Paper and thin tin are commonly referred to as being embossed or debossed, whereas hard substrates, such as metals, wood, hard plastics will use different processes to attain similar effects, such as laser engraving, acid etching, stamping and pressing, or CNC routing and milling. The result is often the same with a raised or depressed part of the surface.

Creating multiple levels of emboss and deboss on hard substrates, when using laser and other machining methods, is not as challenging as doing multilevel effects on soft materials. Furthermore, one needs to keep in mind that when achieving these effects on softer substrates, the required tools can be very expensive and result in larger amounts of wastage.

Other important factors to be considered when embossing and debossing various substrates:

- Avoid embossing across a split line, such as a split door.

- Avoid embossing around the corners of a pack.

- Embossing extremely fine details can increase wastage significantly.

- Trying to deep draw soft substrates can result in tearing and discolouration.

- Embossing excessively large areas on softer substrates can result in a collapse where there is no supporting backfill.

___

IPL Packaging is a global luxury packaging supplier with offices in the USA, Europe, Mexico, Asia and Africa. Approved manufacturing is available in several Asian countries, as well as sites in Eastern Europe. We create bespoke, tailored and exclusive packaging for any premium or luxury brand and manage the entire process, from conceptualisation and design to production and delivery.

For more information on packaging solutions or to get an insight into our latest packaging trends, follow us on LinkedIn, Facebook, YouTube or Pinterest. Keep an eye on our news section for insightful articles and innovative ideas around packaging materials, product development and design.

More articles

January 31, 2023

Guidelines for Sustainable Packaging Creation

October 25, 2022

Navigating ‘Critical to Quality’ Packaging Hurdles

October 27, 2020

The Past, Savoured in the Present – Bowmore

April 19, 2023

IPL Perspectives: Rex Wan & Amanda Comeau

January 25, 2023

Work Feature – Lambay 20 YO

February 1, 2021

Hidden elements that make a difference to packaging quality – Part 1

July 26, 2021

Challenge accepted! …Luxury brands CAN balance consumer preferences AND brand needs through packaging.

August 23, 2022