February 25, 2022

The Whole Truth – A Holistic view of Sustainable Packaging

Whilst the awareness of sustainable packaging is increasing, from many a brand’s perspective it is not often viewed as an integrative or holistic concept. Mostly, perceptions of sustainable packaging solutions are strongly limited to the choice of more sustainable, eco-friendly or biodegradable materials.

Whilst the use of these materials is, of course, increasingly important – what other factors play a role in the production of environmentally friendly packaging besides material choice?

Sustainable Design

Designing products and packaging that reduce consumption across their entire life is really one of the first steps in the cradle-to-grave (or creation to disposal) approach to packaging.

The design stage typically has the greatest influence on a packaging’s life cycle and environmental impact. That is why environmental stewardship must be an integral part of the design and development process, on a par with cost, quality, and manufacturing.

“Implementing design features and functionality such as flat-packable packaging (slimming down the pack to eliminate extra weight and allowing it to be condensed for shipping) or creating products that encourage secondary use, sends a clear message to consumers,” says LB Odendaal, Head of Design at IPL Packaging. “That message is that the brand is thinking of them and their needs, and is going the extra mile to reduce wastage and negative environmental effects.”

However, those involved in the design process, should (as part of the holistic process) also look beyond the features and functionality of a product to consider its raw materials, manufacturing process and transportation efficiencies in order to identify sustainable opportunities in all of these areas.

Sustainable Manufacturing and Processing

There are many financial investors around the world who claim bitcoin/blockchain technology to be the future of money and investment. This may be the case, but often the massive energy requirements to mine bitcoin are overlooked by these pundits as regards to possible impacts on the environment.

Considering sustainable packaging material choices should be no different when analysing the pluses and minuses of different proposed solutions. And, indeed, the way in which different suppliers create their own manufacturing processes may oftentimes have more of an impact on the environment than the end product itself.

Pulp as a substrate for packaging is gaining much more attention, for example. The process to manufacture pulp, however, uses significant amounts of water and energy. Those suppliers using alternative energy sources and who have invested in water recycling systems will impact the environment a lot less than those who haven’t yet made these investments.

Replacing plastic parts and packaging fitments with metal is another example of providing a more ‘sustainable’ packaging solution but also one should consider what the finishing treatment of the metal parts entails: anodizing, spray-painting, electroplating? What do these finishes generate in terms of wastewater and energy? This should be weighed against the fact that the end product is highly recyclable

Much work is being done by material manufacturers to develop substrates that are completely recyclable/biodegradable and alternatives to leather, a popular substrate for luxury products. A few examples are:

- Pinatex – “pineapple leather” made from pineapple leaf fibre (and taking the fashion world by storm).

- Mushroom leather (Muskin) and coconut leather. But each of these requires farmers to re-allocate resources to these crops instead of others, with a consequent impact on the environment.

“Unfortunately, changing material packaging to what is believed to be a more sustainable material can sometimes be short-sighted,” says Mark Castro, IPL’s Head of NPD for the USA “‘Plant-based plastic’ that can replace PET sounds, on the surface, like an ideal solution. However, if no proper recycling is available, packages made from plant-based materials can contaminate the very systems that recycle PET packaging.”

“As a bio-based material, paper products are also a vital alternative. However, to deliver sustainable paper packaging solutions, it’s necessary to ensure the wood is sourced responsibly from well-managed forests. This requires forest certification, a high level of transparency and incorruptible tracking systems.“ he states

“In making luxury brand packaging more sustainable, one should first check to see whether it is possible to use recycled or biodegradable materials. If this is not possible, consider options for using sustainably produced materials.” says Castro.

“Many large brands are working on incorporating these and other sustainable materials and fitments into their product packaging, however in many instances, as long as fossil-based plastics and other substrates are cheaper than recycled or bio-based materials, they’ll primarily continue to choose the more cost-effective solution. Changing this dynamic is commercially difficult, but important too.”

Transportation and Shipping

It appears it will always be possible to make greener choices across the packaging supply chain. This includes shipping, storage, delivery and final product distribution. Streamlined and more efficient logistics and transportation solutions can significantly reduce waste and emission – ideal for brands that hope to shrink their carbon footprint.

However, whilst turning a traditional supply chain green doesn’t happen overnight, it all starts with analysing how to make more environmentally friendly choices at every step. It goes without saying that streamlined logistics practices can significantly minimise environmental harm and enhance a product’s overall sustainable credentials.

That could mean anything from packing trucks or shipping containers more efficiently to achieving optimal fuel efficiency during ground transportation. Lighter shipments of sustainable packaging not only reduce transportation costs, but also reduce the amount of fuel during transportation.

In some instances, one of the most impactful ways to reduce transportation emissions is to align with packaging suppliers who have factory partners situated closer to clients or at high points of demand.

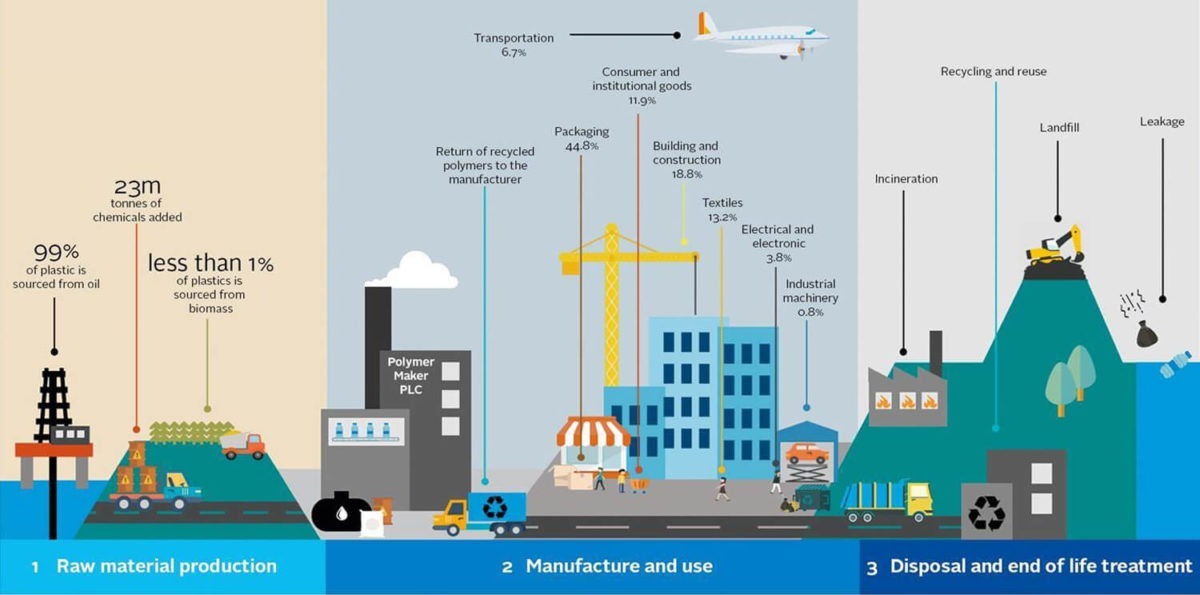

A Lifecycle Mindset – a granular approach

© Unpri.org

Simply put, every activity a packaging supplier performs bears a social, economic, and environmental impact. However, often these impacts are not unearthed until the complete lifecycle of a particular packaging solution is examined.

“This involves looking at the bigger picture – analysing manufacturing processed vs. materials, designing with a sustainable mindset and looking to optimise supply chain logistics. Ultimately, what happens at the end of the packaging’s life, is so crucial to understand,” states Castro.

“Brands must understand, at a granular level, how their consumers buy and use the products in their given category and how consumers dispose of the packaging,” he says. “These insights can serve as a starting point for an analysis of which kinds of sustainable packaging fit a given value chain and the range of improvement levers available.”

Conclusion

Whilst global packaging suppliers continually test and trial sustainable material alternatives, we’re still a big step away from a world completely free of packaging waste. Perhaps because many brands are too intent on considering a part of the problem (materials) and not the whole (incl. systems and processes).

There are also solutions in the area of packaging today that function in good, streamlined processes and systems and therefore demonstrate truly sustainable properties. This is an exciting and ongoing process, one that is likely to continue indefinitely as brands and suppliers work together to reinvent and simplify sustainable packaging approaches that combine material testing and trialing machine learning, materials and solid client-supplier and supplier-manufacturer partnerships to scale sustainable change across the packaging supply chain.

IPL Packaging is a global luxury packaging supplier with offices in the USA, Europe, Mexico, Asia and Africa. Approved manufacturing is available in several Asian countries, as well as sites in Eastern Europe. We create bespoke, tailored and exclusive packaging for any premium or luxury brand and lead the entire process, from conceptualisation and design to production and delivery.

For more information on packaging solutions or to gain insight into our latest packaging trends, follow us on LinkedIn, Facebook, YouTube or Pinterest. Keep an eye on our news section for insightful articles and innovative ideas around packaging materials, product development and design.

Article Contributors:

LB Odendaal | IPL Head of Design | Connect on LinkedIn

Mark Castro | IPL Head of NPD USA | Connect on LinkedIn

Kirsten Hill | IPL Content & Insights | Connect on LinkedIn

More articles

October 7, 2020

Promoting The Luxury of Tomorrow – Walpole

April 6, 2021

Tin is a luxurious and sustainable packaging material

December 7, 2022

High Score – FIFA World Cup Replica Trophy Case

October 25, 2022

Navigating ‘Critical to Quality’ Packaging Hurdles

June 5, 2024

Rosebank Whisky Blooms with Elegance

September 7, 2020

The VR (very real) benefits of VR in packaging

October 27, 2020

The Past, Savoured in the Present – Bowmore

April 21, 2022