March 28, 2023

Case Study – FIFA Replica Trophy Case

The Brief

We were approached by our client to design and manufacture a luxury display case to house a 1kg solid gold, 24kt, replica of the 2022 FIFA World Cup Trophy.

The high value of the contents required the case to be of the highest quality. It was also communicated that special attention needed to be paid to material choices and finishes. A perfect mix of detail and displayability would need to be considered.

A target price and unit amount was subsequently agreed upon, enabling our teams to work within a realistic budget and explore a range of potential design solutions.

As the project progressed, timing constraints and the availability of fittings, for example, sought to impact several aspects of the design. Targeted pricing was then adapted at several stages to allow for the delivery of an exemplary product, both on time and within budget.

IPL worked in close collaboration with the client to manage all expectations, retaining transparency and open lines of communication when revising concepts.

The Research and Ideation Phase

As the final product was an official FIFA-approved product, strict guidelines needed to be adhered to in the representation of the FIFA Qatar 2022 brand. We worked closely with the client in reviewing and interpreting these guidelines and incorporating the necessary brand language into the proposed concepts.

Due to the complex nature of stakeholder relationships, we often found ourselves following multiple, and sometimes complex, channels of communication in order to obtain signoff on concept, artwork, samples and production.

The above challenged us to preemptively devise possible solutions to potential or anticipated challenges so that, should a specific issue lead to timing or costing issues, a well-considered solution could be seamlessly implemented.

Review and Decisions to Pursue a Defined Direction

Several design directions were ultimately presented to the client. These drew inspiration from several diverse sources.

A point arose around the representation of the FIFA identity and some conflict with an already existing product, of which we were not aware. We subsequently implemented several significant alterations to the original concept direction and these were then reviewed.

Once the client had an opportunity to review our initial submissions, we received feedback on a preferred direction.

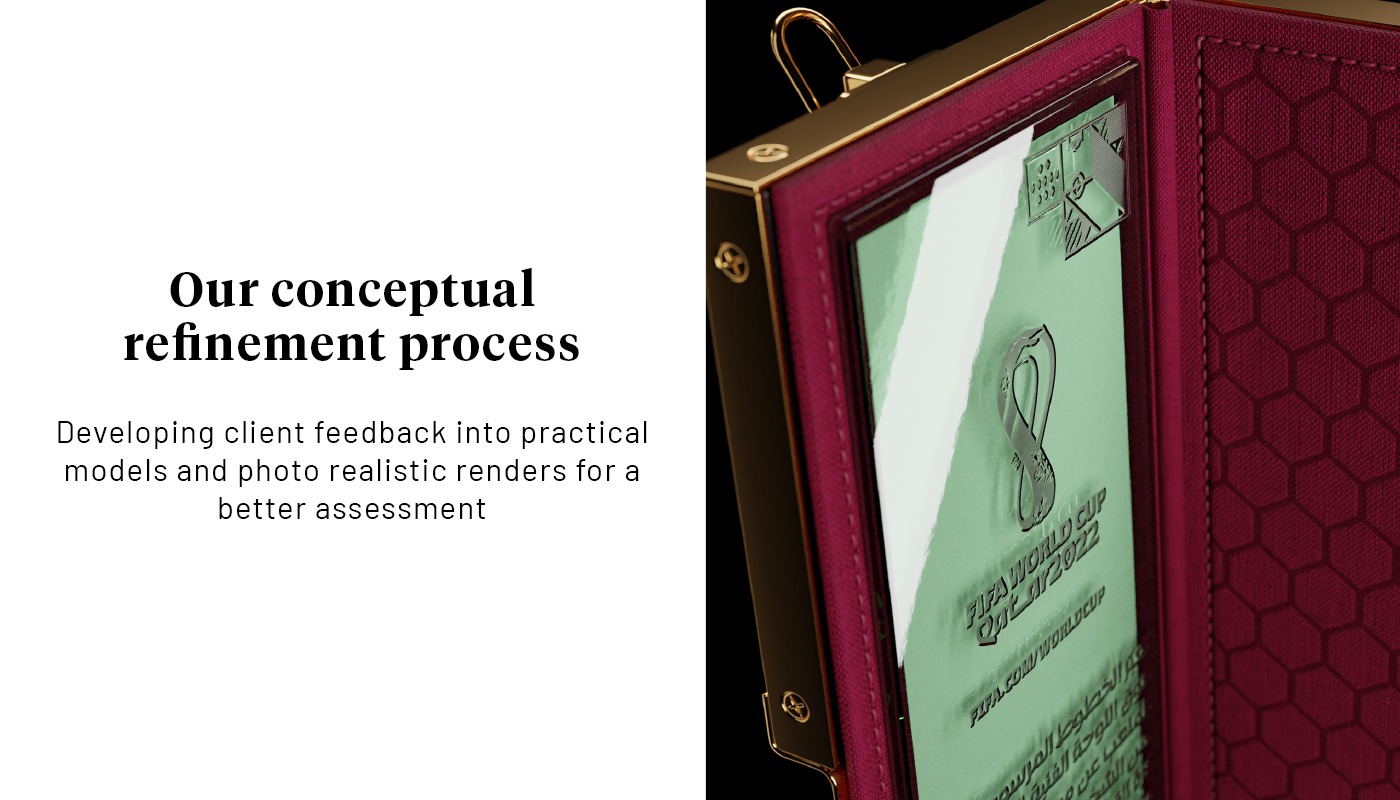

Development of Designated Design Direction

Work continued in a specific direction, with further consideration given to material choices, manufacturing processes, timing and the availability of resources.

During this process, several alterations and enhancements were made to the proposed packaging designs in order to further accommodate changes in timing, budget and the complexity of the engineering processes.

The scope of the project was altered to a point where the original designs, proposed development, timing and material costs were reviewed and solutions were proposed and then introduced.

These revisions culminated in a reduction in overall costs and time-to-market through the alteration, and sometimes removal, of more bespoke elements of the design.

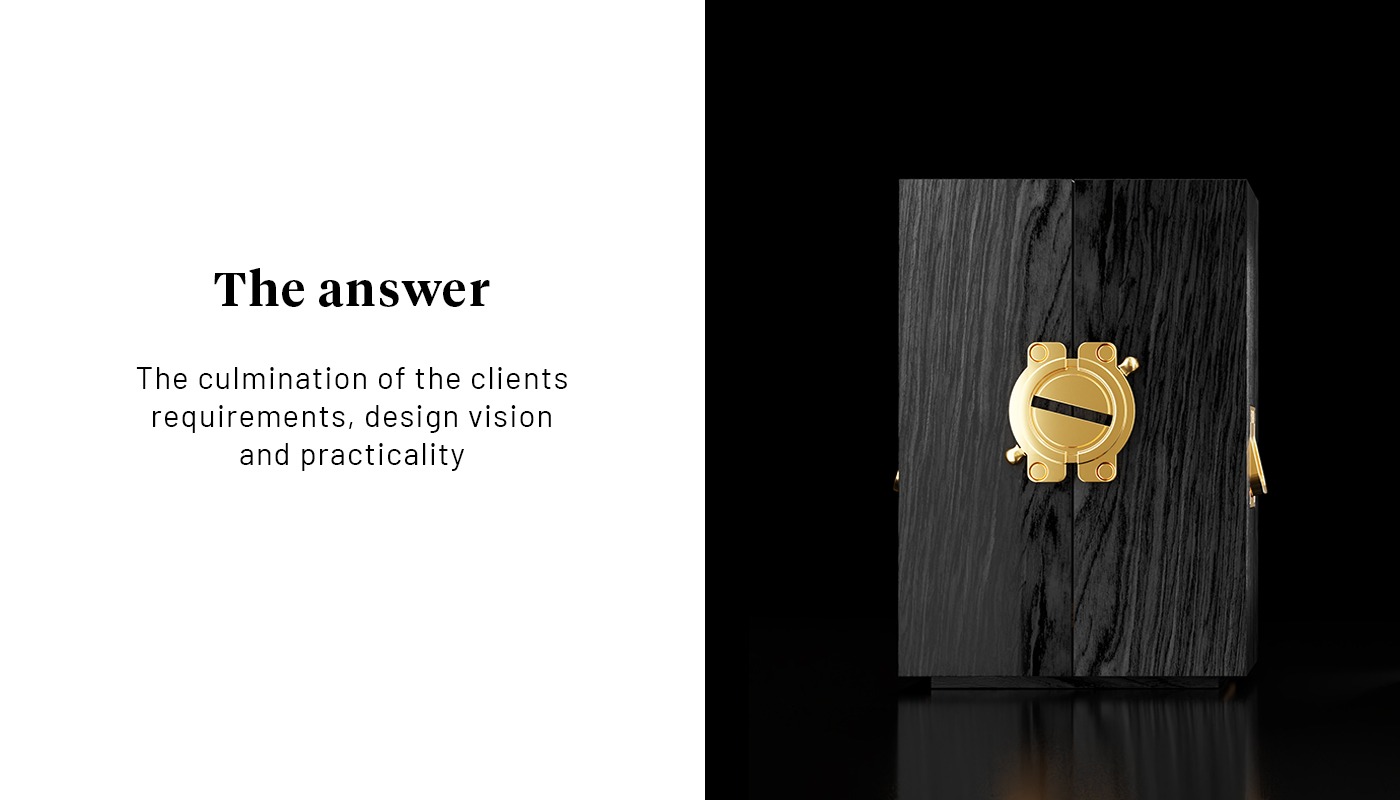

Presentation of Final Design

Once all parties were satisfied with the design and material choices, the costing and timing plan were presented to the client for approval, in order for sampling and engineering to commence.

After several rounds of development, a final design was approved.

Production

The bespoke nature of the product called for the highest level of craftsmanship in manufacturing. The quality of the unboxing experience, the impact of ‘the reveal’ and the user interaction were all key factors.

We spent a large amount of time testing and refining the mechanics of the opening mechanism and its workings. Attention to detail in assembly and finish was carefully monitored and controlled

A relationship established with a new manufacturing partner helped us to propose some key alterations to the hardware used and to save critical time in production. These changes took into account the impact of the final unboxing experience and weighed it up against the potential delay in delivery should no change be made. We reached a conclusion with the client and the manufacturer that all parties agreed upon.

Delivery of the Final Product

IPL successfully delivered an exceptional piece of high-end secondary packaging in time for a worldwide release before the 2022 FIFA World Cup kicked off in Qatar.

The end product showcased the best in design, production planning, material selection, mechanical ingenuity and craftsmanship. Our own goal was achieved; to present designs that best achieve our client’s exacting requirements, whilst demonstrating our deep understanding of the manufacturing processes and delivering within an achievable framework.

For more information on packaging solutions or to gain insight into our latest packaging trends, follow us on LinkedIn, or join our community of packaging enthusiasts by signing up to our monthly newsletter below. Keep an eye on our news section for insightful articles and innovative ideas around packaging materials, product development and design.

More articles

October 25, 2022

Navigating ‘Critical to Quality’ Packaging Hurdles

November 14, 2023

The Battle for Sustainable Packaging Supremacy

March 27, 2024

Packaged Like Stars

June 29, 2023

Unpack(ag)ing: Service in Today’s World

May 4, 2022

The Costs of Conflict

February 13, 2024

The Psychology of Luxury Packaging…Unwrapped

February 24, 2021

Giving it Gears: The art of steampunk

August 22, 2023