November 5, 2020

Simple packaging errors to be avoided

In the packaging industry, simple errors can be made during both the design and manufacturing stages. With care, these can be avoided. While most processes in mass production packaging are automated, the higher-end luxury and premium sectors often have a greater labour component. This ensures exclusivity, but it can also be a source of errors in production. For this reason, quality control checks and visual inspections allow brands to find these mistakes and rectify them as soon as possible.

Sometimes, these errors are the result of a simple oversight or, possibly, they are made during a trial-and-error process to achieve a certain finish. Whatever the cause, here are four common packaging errors that brands can make and suggestions on how to fix or prevent them from occurring.

1. Design and artwork errors

Design and artwork errors are made before production. These can include simple spelling errors or visual problems, such as a shifting die line and misalignment of the artwork. Sometimes, these layout and visual mistakes are hard to see until they are printed out and wrapped onto a three-dimensional box in the sampling or pre-production stages.

Where there are variants of a design that will be printed on different iterations of a product in mass production, mistakes can creep into the packaging run. Dieline changes must be implemented in the layout before mass production of each variant.

Design, layout and artwork errors need to be picked up as soon as possible. They are impossible to rectify once products are manufactured, distributed and sold. These problems can often be avoided by following a certain set of parameters, from conceptual design mock-ups through to prototyping and pre-production, where strict oversight and quality controls are performed at each stage. This will ensure that these potential errors are picked up and rectified in time before becoming costly mistakes or affecting brand image in the marketplace.

2. Printing and production errors

Printing errors can occur during the print production process. Common examples of printing errors include out-of-register print layers, colour shifts when varnishes and coatings are applied, as well as contamination from dust or dirt on print plates. Registration and color matching are two areas that need constant attention during the printing process but these can be avoided if production runs are closely monitored by the press master and his printing team, using a light table along with other sophisticated light-measuring equipment.

When printing in cyan, magenta, yellow, black (CMYK), each press pass adds another colour on top of the previous one. If the print plates are not property aligned (because of incorrect jigging), there can be an overlap of colours. Print runs can include 12 colours, so registration issues can become even more challenging with high wastage. Using highly-viscous spot varnishes over existing print may sometimes shrink on drying and pull back on themselves, leaving a varnish finish that is out of register.

Print errors that are not identified immediately and carried through to the end of a run can become costly as the entire lot then needs to be scrapped. If substandard print is passed to the manufacturing line for wrapping and finishing, the wastage costs will increase significantly due to high-quality rejections of the finished product. Compounding this are delays in delivery, which can then lead to very costly airfreight in order to meet deadlines.

3. Product integrity and fitment

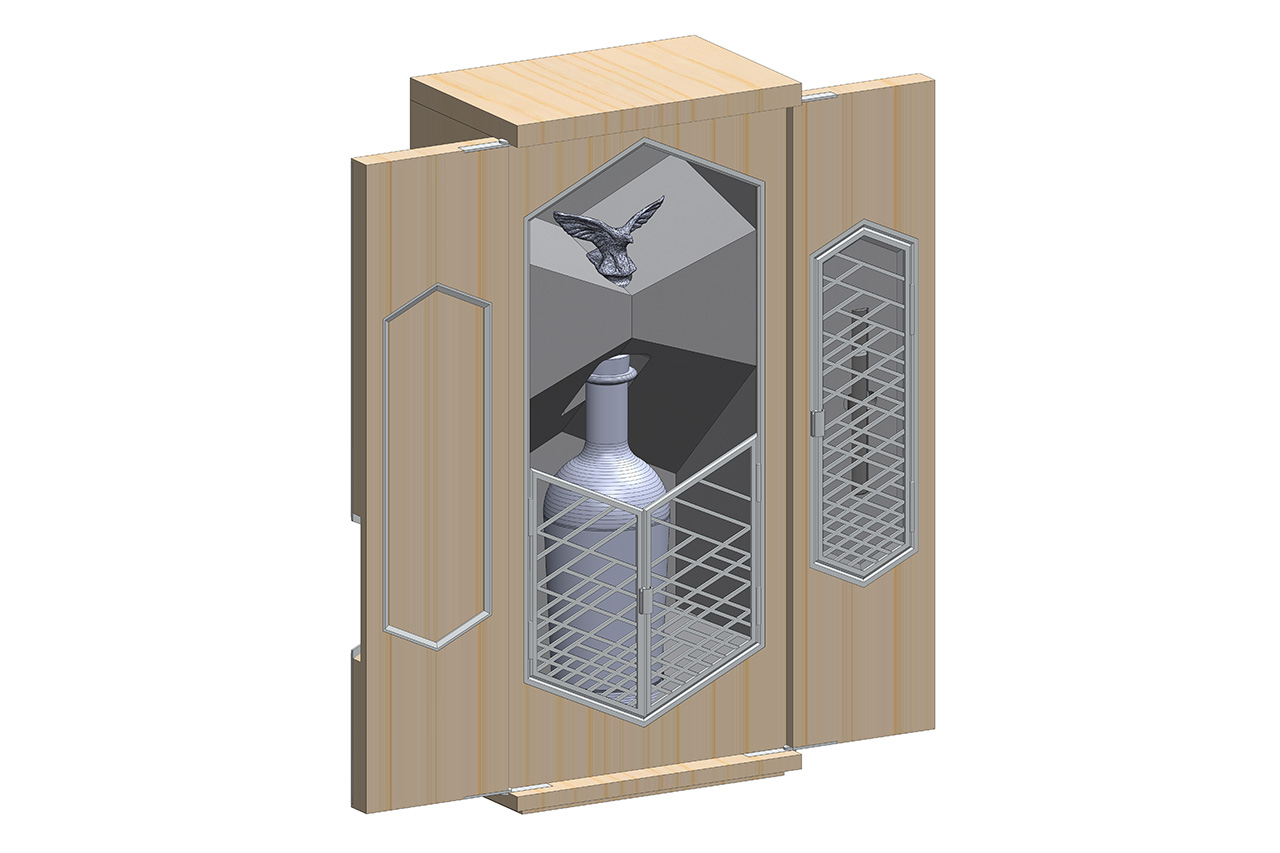

Many brands rely on some sort of inner fitment within the packaging to hold the primary product in place. This fitment can be made of a number of different materials and can be inserted for a number of different reasons, including being part of the aesthetic make-up of the pack. Importantly, the inner fitment is often included to protect the primary product when the package is moved about during transport.

This ensures that the important branding elements on the product are correctly aligned when the package is opened. If the inner fitment is too loose, it may not perform as intended and the primary product could shift around. If the fit is too tight, it can make the removal of the product from the pack very difficult, resulting in an extremely frustrating consumer experience.

There are tests that can be performed to avoid fitment issues and protect product integrity. These include usage tests, where the primary product is inserted and extracted a number of times; security tests, where the loaded pack is turned face-forward to ensure it doesn’t open; and climate tests, where the pack undergoes extremes of temperature and humidity.

4. Transit damage

Even if a perfect pack is designed for a product and it looks and performs as intended, issues can arise during transportation. If the pack does not perform well during transit and either the product is damaged or the packaging itself is damaged, it can lead to a massive waste of time, money and effort. Damaged products and packaging can also have a negative effect on the intended brand experience.

Products often undergo rough handling and shipment during road, sea, air or rail transport. Ensuring that the package will handle travel well is vital before mass production starts. Transit tests are often conducted before shipment. These include drop tests, where a shipper of loaded packs is dropped from a certain height, as well as a vibration test, whereby a shipper of loaded packaging is subjected to a vibration table for a number of hours. This purposefully-designed test ensures that neither products nor packaging are damaged during bumpy transit.

These are some examples of packaging errors that can affect products and brands. They are usually easy to address, provided they are spotted early in the development or production processes. By paying attention to the small details, brands can eliminate as many mistakes as possible and avoid lengthy delays, which can have profound cost implications.

___

IPL Packaging is a global luxury packaging supplier with offices in the USA, Europe, Mexico, Asia and Africa. Approved manufacturing is available in several Asian countries, as well as sites in Eastern Europe. We create bespoke, tailored and exclusive packaging for any premium or luxury brand and manage the entire process, from conceptualisation and design to production and delivery.

For more information on packaging solutions or to get an insight into our latest packaging trends, follow us on LinkedIn, Facebook, YouTube or Pinterest. Keep an eye on our News section for insightful articles and innovative ideas around packaging materials, product development and design.

More articles

December 8, 2020

A ‘New Normal’ in Packaging for Traditional Luxury Brands?

November 27, 2020

(Re)imagine packaging: 50 shades of the future

September 15, 2022

Societal Shifts and their Impact on Packaging

January 31, 2023

Guidelines for Sustainable Packaging Creation

February 21, 2023

Work Feature – Brugal 1888

November 16, 2020

Arran 21 YO – A Luxury Packaging Awards Finalist

October 22, 2018

A Tin to Tell a Story

June 17, 2021