October 2, 2018

Breaking Packaging Boundaries

For packaging suppliers operating in today’s global economy, amidst the reality of shifting markets, the importance of consistently exploring opportunities with new, strategically placed production facilities cannot be overstated.

“Strategic sourcing can really assist clients in best meeting their procurement objectives without compromising product quality or supplier service levels and, whilst IPL’s manufacturing operations in China are well established and undoubtedly will remain very key to our ability to produce quality product; on time and within budgets, the fact is that other opportunities for supply increasingly present themselves,” says Christiana Delahaye, IPL Packaging Senior Purchasing Manager Europe.

“We need to ensure we’re fully exploring these opportunities and continuing to break barriers in terms of market entry and exploration. With this in mind we’re continually looking at innovative design and material options across all our packaging solutions,” she says. “We also continue to review our current production facilities and investigate and test new global suppliers to ensure we’re best addressing our client’s needs around budget, materials, transportation and the like.”

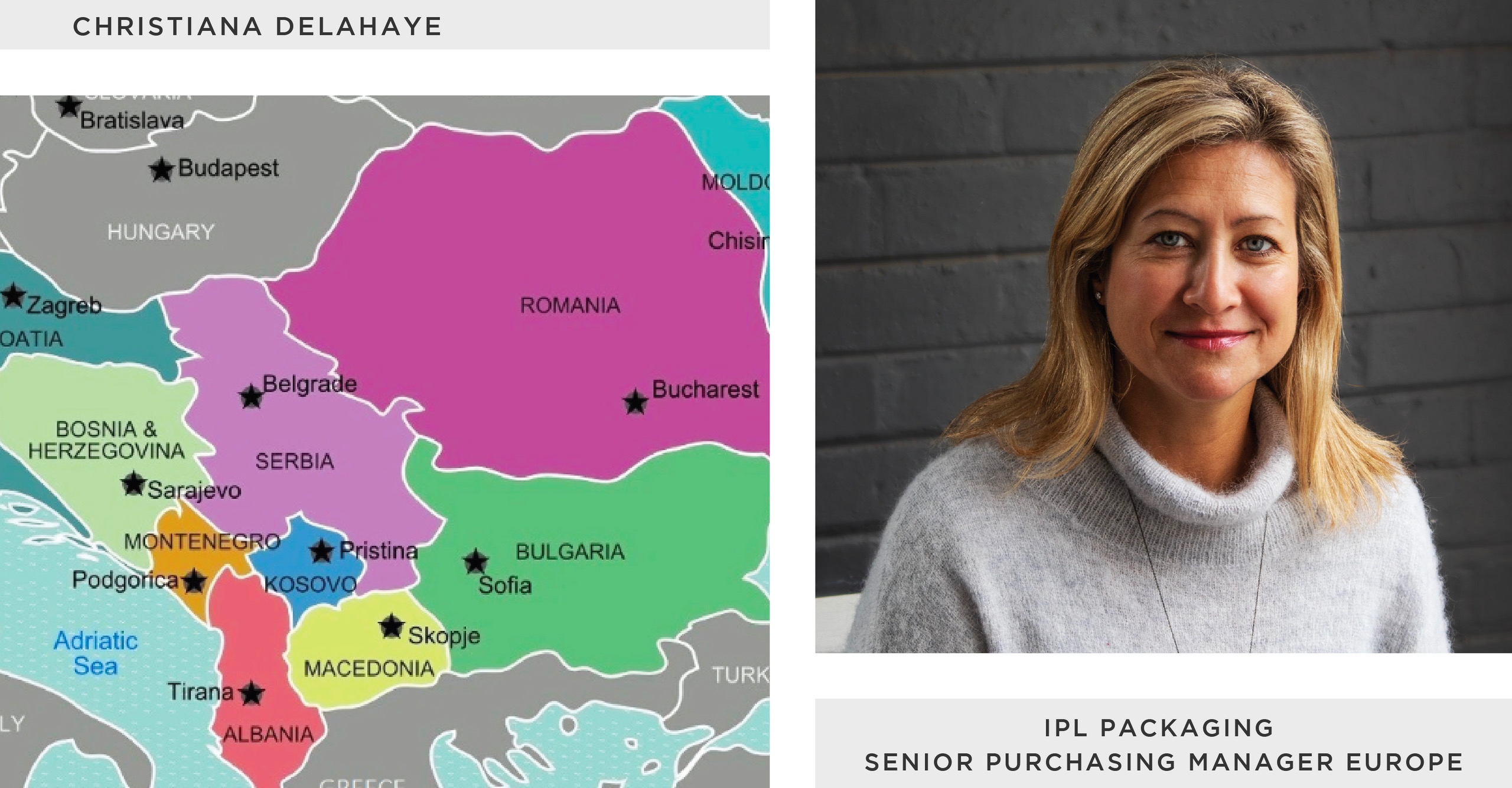

“In exploring new markets, language and cultural barriers can often present real challenges in terms of interaction between supplier and manufacturer,” Christiana explains, “possibly leading to opportunities missed or misinterpreted. On a recent business trip to the Eastern Balkans my ability to speak several European languages was a great advantage,” she admits.

“Prior to the trip I was able to challenge many of the production facilities with ‘live enquiries’ to test reaction times, costings, operational capabilities and delivery timelines. I was subsequently struck by the professionalism, quality of service and high-quality machinery present at many of sample companies and manufacturers I met with.”

“Naturally not all Eastern European and Balkan countries are created equal in terms of core capabilities, packaging industry history circumstances or environments,” says Christiana. “Poland for example is already fairly advanced as a packaging manufacturing hub and boasts a long and impressive history in this sector. Though here labour and overhead costs are getting closer to the Western European’s,” she explains.

“However, several other East Balkan countries, especially those such as Bulgaria, Serbia and Macedonia, now offer great opportunities for engagement with both 3D sampling/ prototyping companies as well as packaging and printing facilities. In particular, printing, plastic and paper industries in many of these states are becoming highly advanced, with most of these facilities boasting modern equipment and state-of-the art machinery along with reasonable costs and competent labour forces. Production facilities for other high-quality packaging materials such as MDF, wood and rigid board present themselves equally impressively.“

There is much untapped potential in this area as these counties continue to make strides (with the support of the European Union) towards enhanced economic growth, improved transportation networks and the introduction of systems and investments favourable to machine building and industry. Furthermore the proximity and ease of transport to other European markets cannot be overlooked,” explains Christiana.

“For IPL this certainly a ‘space to watch’ as we continue to assess and explore several strategically placed production facilities worldwide,” she says. “When it comes to addressing critical issues of sustainability, controlling quality, delivery, quantity, price and all other factors embodied in the design-to-delivery production packaging cycle – ultimately it comes down to matching client needs with opportunities and industrial capacities and this is something we’ll always place at the forefront of our business.”